- manufacturer and supplier of steel elements and constructions

RIGHT SOLUTIONS

MANY APPLICATIONS

TODAY, TELEDOOR HAS A HISTORY OF SUCCESS OF OVER THIRTY-FIVE YEARS AND IS RECOGNIZED ON THE INTERNATIONAL MARKET.

35 YEARS

SINCE 35 YEARS, WE HAVE BEEN SUCCESSFULLY COMBINING TRADITION WITH MODERN SOLUTIONS, ENSURING THE QUALITY AND VERSATILITY OF OUR SERVICES.

12 000 m2

Production area in our plants is more than 12.000m2, which allows for large-scale operations.

TRADITION

& MODERNITY

TELEDOOR maintains traditional fundamental values and is simultaneously progressive with regard to technology, products and services.

- TELEDOOR is a trustworthy company

FOUNDED IN JANUARY 1986

OWNER-MANAGED IN THE SECOND GENERATION

COMPANY HEADQUARTERS IN MELLE NEAR OSNABRÜCK

MORE THAN 220 EMPLOYEES

12 000 m2 PRODUCTION AREA

OWN AGENCIES IN SHANGHAI AND MOSCOW

ADDITIONAL PRODUCTION FACILITY IN TAICANG, CHINA

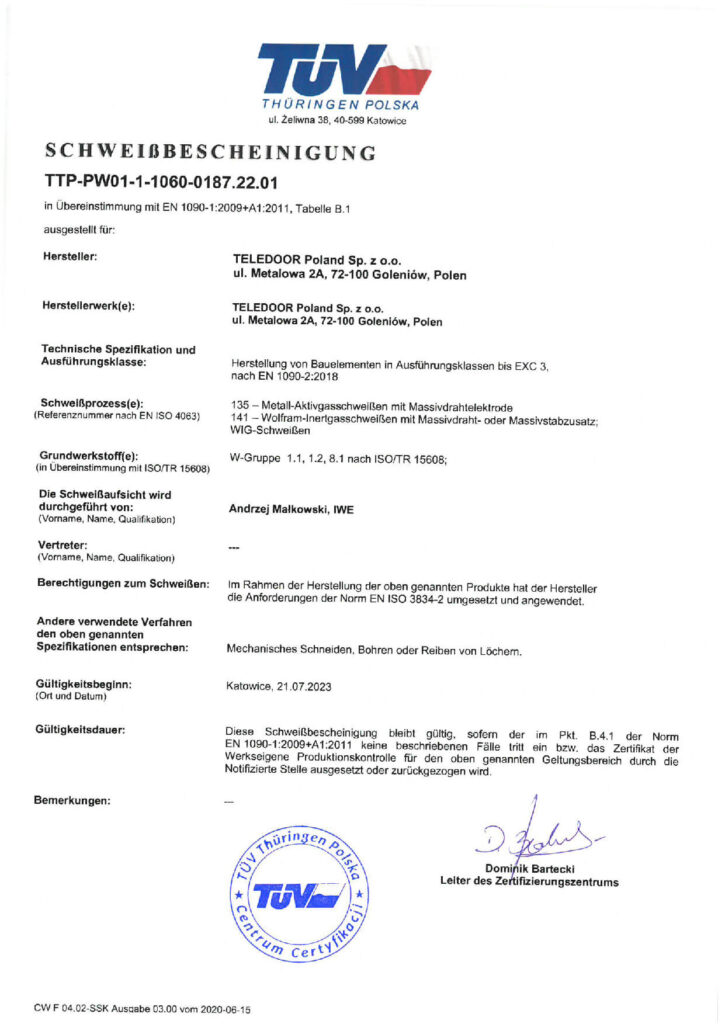

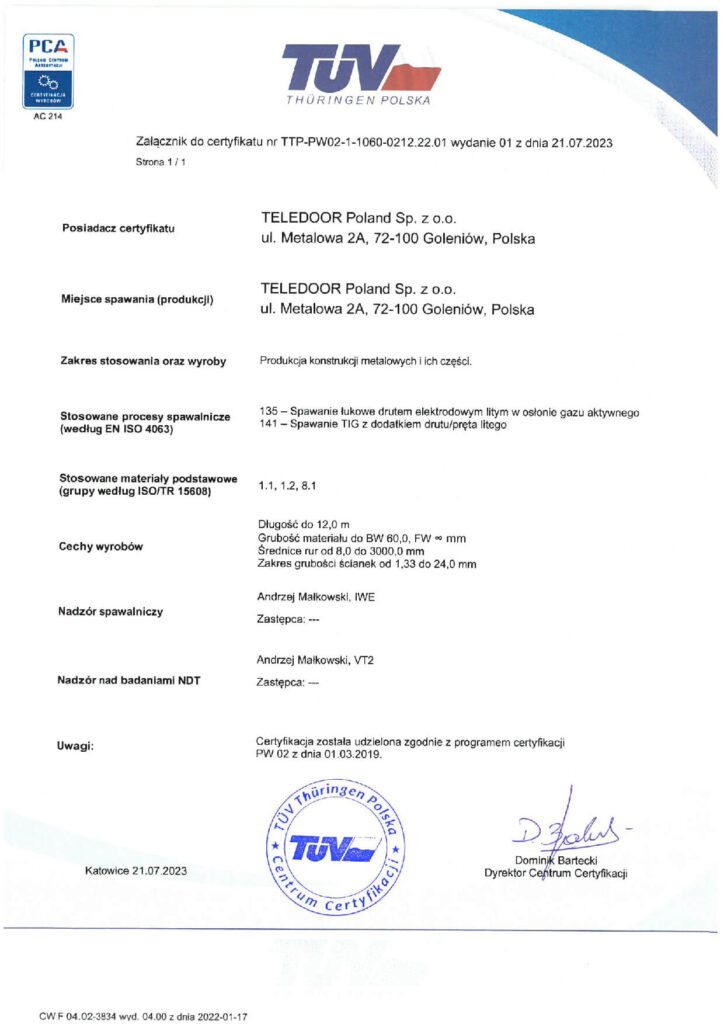

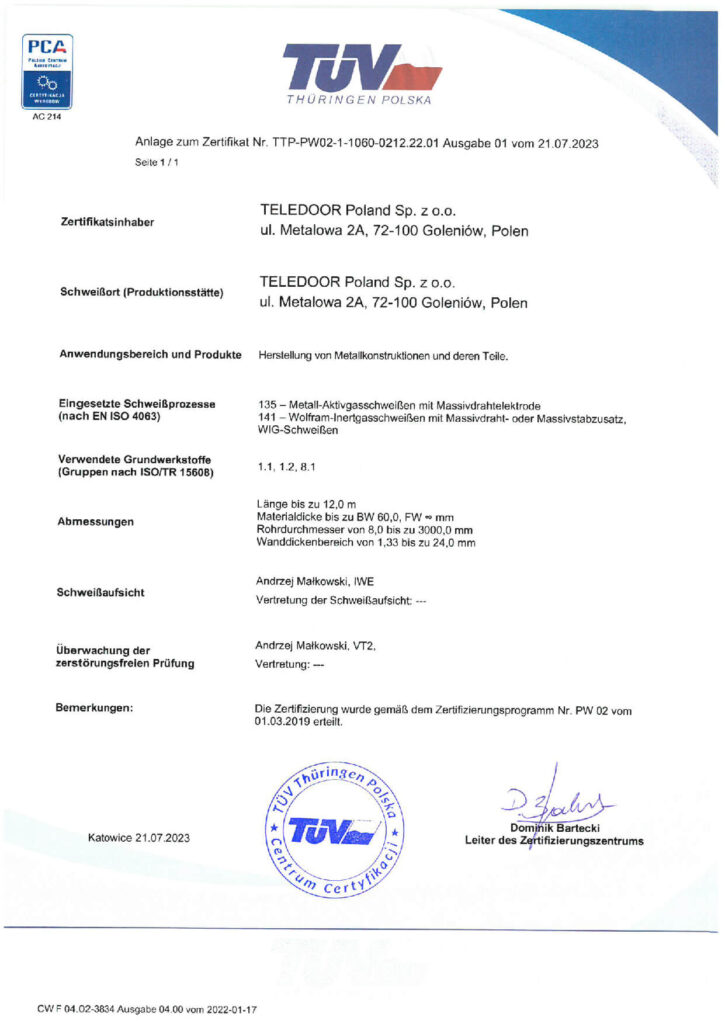

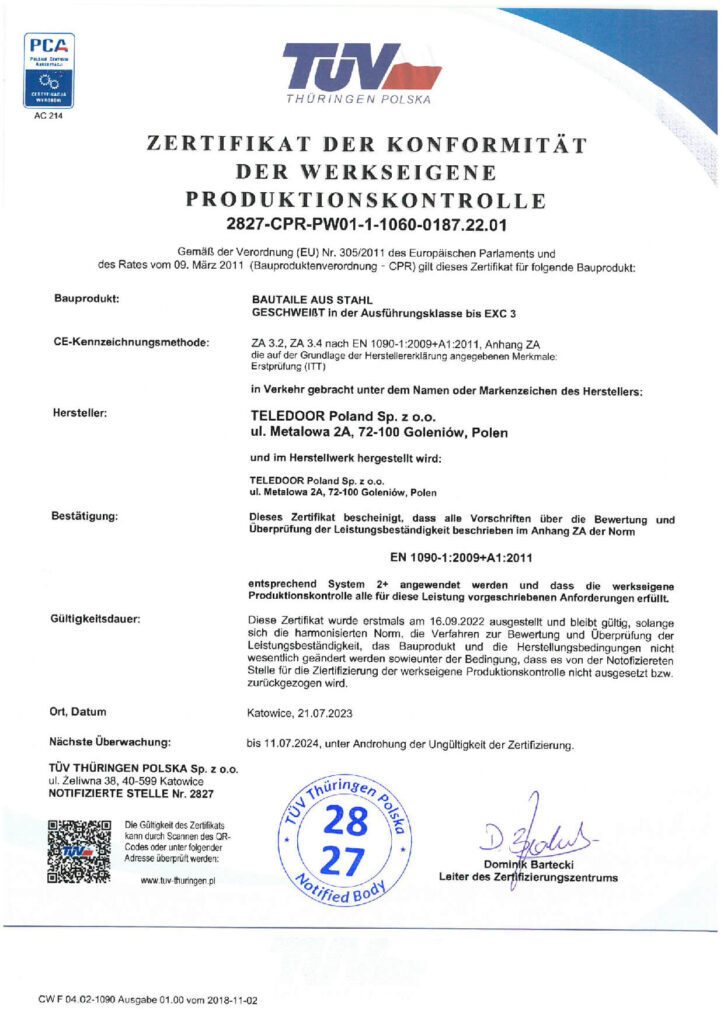

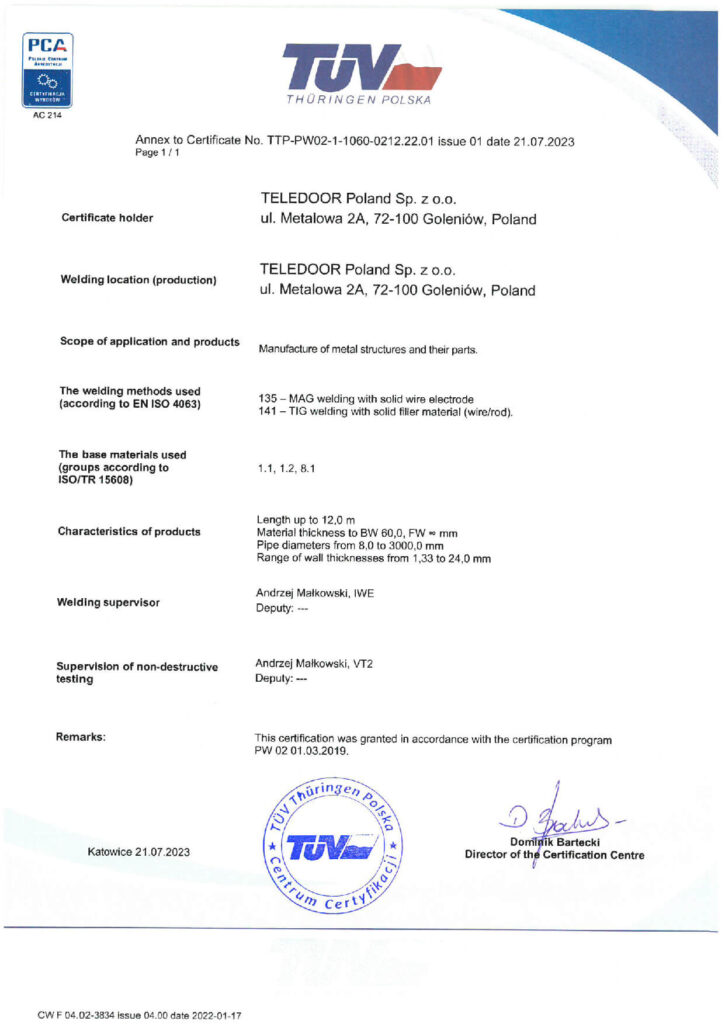

NEW PRODUCTION FACILITY OF TELEDOOR POLAND, IN GOLENIÓW, POLAND

- Experience in innovation

A PROVEN PRINCIPLE FOR MULTIPLE AREAS OF APPLICATION

To meet current requirements for steel structures in system and industrial construction, you need modern and reliable solutions. Teledoor Poland is a partner you can rely on. The new steel construction division consists of a thirty-person team with over 20 years of experience in the industry.

You will receive customised, complete solutions from a single source. Our designs take all of your specified load-bearing capacities into account, and we handle all structural calculations for you. Of course, we also handle transportation and ensure quick and smooth installation by pre-assembling as many elements as possible.

- Our

SERVICES

- Career

JOIN THE TELEDOOR POLAND TEAM

We are happy to meet people with whom we share the same vision. Write to us, if you want to cooperate — maybe you are the one we are looking for!

Contact us

PRODUCTION FACILITY

Teledoor Poland Sp. z o.o.

ul. Metalowa 2A

PL 72-100 Goleniów

BRANCHES

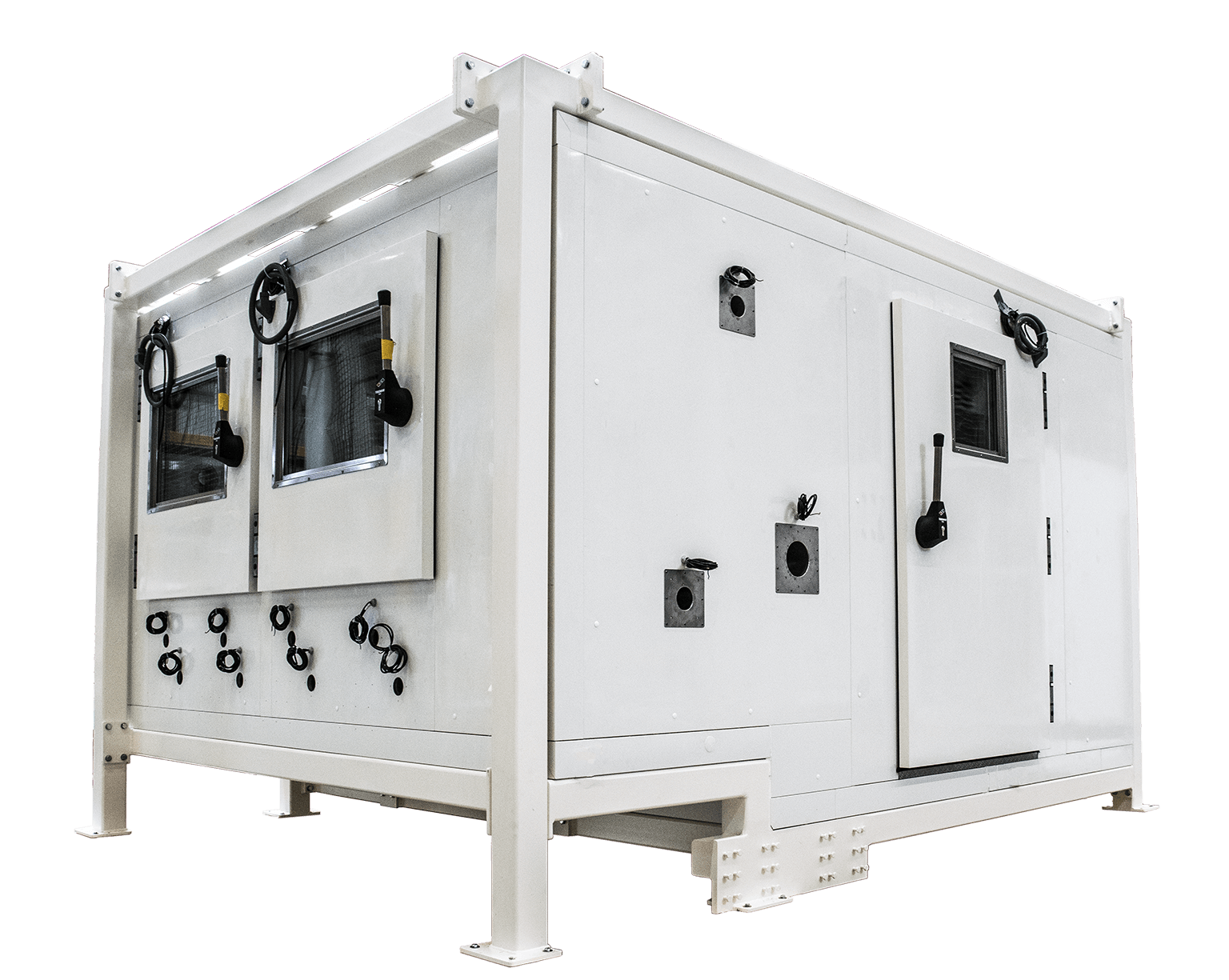

Chiller and freezer cells, Climate and test cells, Machine claddings

Clean room technology